Rockets

Learn about all of our team rockets

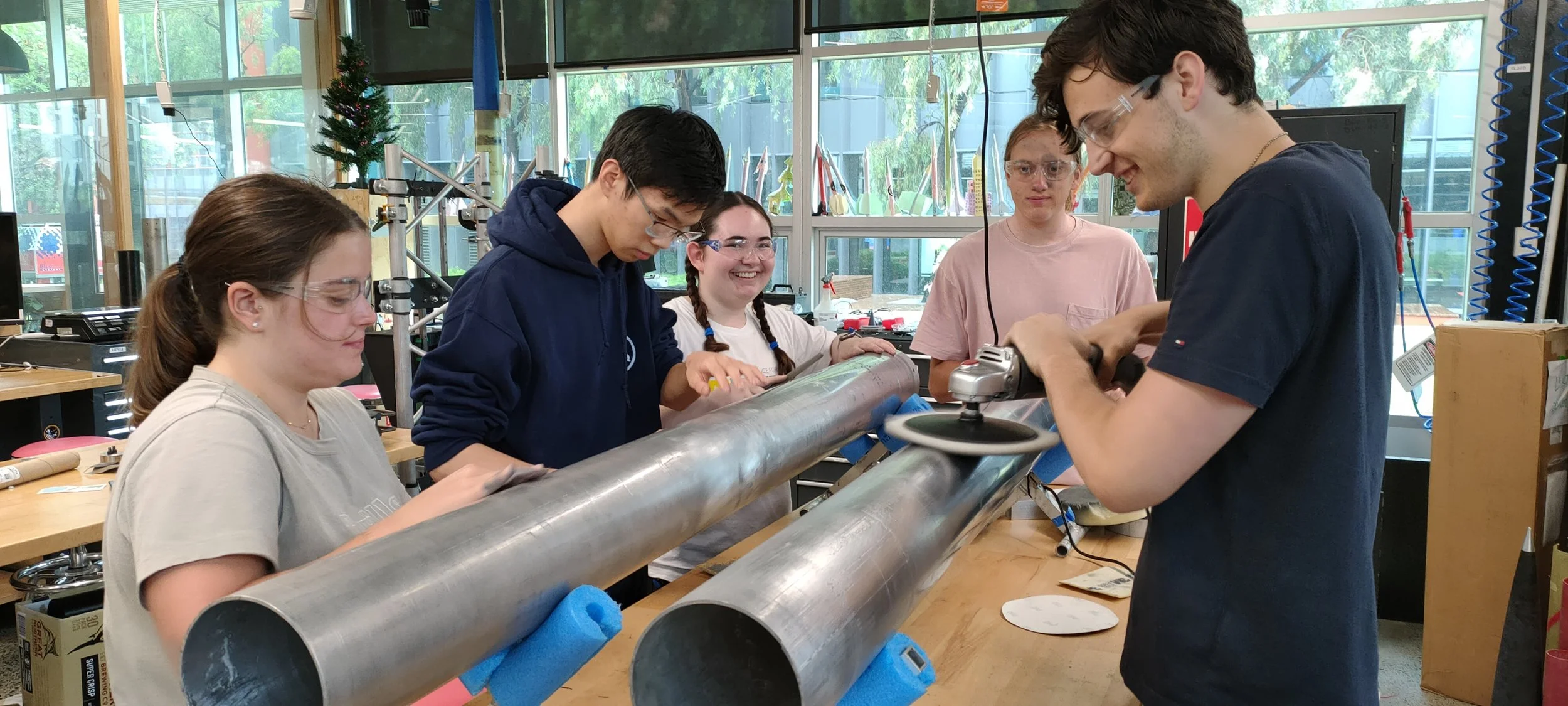

Project Wyvern was developed for the 5,000 ft COTS (commercial off the shelf) category in AURC (Australian Universities Rocket Competition). Project Wyvern is propelled by a pre-purchased K400C motor, providing a peak thrust of 544N and a total impulse of 1307Ns. Wyvern carried Project IVAAn (Intraocular Vision Acuity Analysis) as its payload, using a camera in order to test the effect of flight on the human eye. A dual deployment system was implemented, powered by a primary (Blue Raven) and redundant (RRC3) flight computer. This project is the first time that the team has introduced a second rocket into our developmental cycle. In previous years the team has come together to work on one rocket, however we are now giving newer members an opportunity to take on new challenges and develop their skills.

| Airframe Length | 1710 mm |

| Airframe Diameter | 78.2 mm |

| Motor | K400C |

| Peak Thrust | 544 N |

| Total Impulse | 1307 Ns |

| Burn Time | 3.26 s |

| Mass With No Motor | 4.596 kg |

| Mass With Motor | 5.79 kg |

| Project Leads | Amy Pang, Jayanth Shivanand, Dasun Mahamadachchi |

| Competitions | AURC 5000ft category (runners up) |

| Payload | IVAAn - Intraocular Visual Acuity Analysis |

Over a two-year cycle, Monash High Powered Rocketry is developing Project Zenith to compete in the 2025 International Rocket Competition (IREC). Drawing from past rockets, Zenith fosters innovation as the team’s first entry in the 10,000 ft SRAD hybrid/liquid propulsion category, powered by an in-house engine.

Zenith’s custom hybrid engine, Solaris MkII, uses liquid nitrous oxide and a paraffin wax fuel grain. Solaris MkII is a groundbreaking achievement as Australia’s most powerful student designed and manufactured hybrid engine.

Zenith carries three experimental payloads:

Avionics Bay: housed in the nosecone, it includes three SRAD flight computers—Strelka, Tycho, and KIMU v2—that record and transmit high-fidelity position data.

MEMS Sensor Experiment: investigates high-precision inertial data production using smartphone-grade MEMS sensors, housed in a 4U CubeSat chassis.

Air Brakes: the team’s first active control system adjusts drag in real-time to achieve a 10,000 ft apogee. Operated by the SRAD flight computer, Strelka, and supported by Dynamics' modelling and simulation.

Zenith's recovery uses a single-bay, dual-event system with SRAD dual-redundant devices, deploying a drogue at apogee and main parachute at 1,500 ft. The Galileo Flight Computer (GFC) v3 controls deployment with redundancy from the BlueRaven altimeter.

Trajectory and safety are modelled by SATURN, an in-house 6-DOF simulator, now updated for Solaris MkII and Air Brakes.

The airframe, fully designed and manufactured in-house, combines fiberglass, carbon fiber, and aluminium, showcasing iterative design in complex integrations like nosecones, fin wraps, a powerful engine, and air brakes.

| Airframe Length | 3180 mm |

| Airframe Diameter | 156 mm |

| Motor | Solaris MkII (M3400*) |

| Peak Thrust | 4,000* N |

| Total Impulse | 10,000* Ns |

| Burn Time | 3* s |

| Mass with no motor | 22.6 kg |

| Mass With No Propellant | 24.8 kg |

| Mass With Propellant | 31.8 kg |

| Project Leads | 2024-25: Johnson Zheng & Aryaman Mangwani 2023-24: Megan Robinson & Jonathan Lantouris |

| Competitions | 2025 International Rocketry Engineering Competition - 10K SRAD Hybrid/Liquid Category |

| Payload | Microlith - Investigate methods of producing high precision inertial data from Smartphone grade sensors. Air Brakes |

Monash High Powered Rocketry's entry into the 2023 Spaceport America Cup is Project Valkyrie, competing in the 10,000 ft Commercial-Off-The-Shelf (COTS) solid propulsion category. With a new generation of students joining the team at the end of lockdown, Valkyrie was designed to establish a strong foundation of systems engineering and develop rocketry experience. The payload is housed in a 4U CubeSat structure and designed to study the effects of microgravity on intravenous blood transfusions, as well as the impacts of high accelerations on the integrity of blood. Additionally, many on-board Student Researched and Developed (SRAD) systems developed by the team are employed in the rocket: an in-house manufactured nose cone, 360 degrees of on-board footage, Laika V3 to log high-quality telemetry data, and the Galileo Flight Computer to control redundant deployment of the rocket's recovery hardware. A dual-deployment system is utilized with a 36" drogue parachute deployed just after apogee, and a 96" main parachute deployed at 1,500 ft. High-precision computer-aided design and mass estimations allow for SATURN, our in-house 6 degree of freedom trajectory simulator, to accurately predict apogee and stability. Coupled with the adjustable ballast system, SATURN can account for weather and atmospheric conditions at launch to optimise the mass of the vehicle to achieve the target apogee.

| Airframe Information | TBC |

| Airframe Diameter | 156 mm |

| Motor | M3400 |

| Peak Thrust | 3893 N |

| Total Impulse | 9995 Ns |

| Burn Time | 2.92 s |

| Mass with no motor | 22.6 kg |

| Mass with motor | 30.9 kg |

| Project Leads | Ranuli Illankone & Caroline Lee |

| Competitions | 2023 Spaceport America Cup - 10K COTS Category |

| Payload | Microgravity and High Acceleration Blood Transfusions - Study the risks associated with performing blood transfusions at microgravity, as well as the effects of high accelerations on the integrity of blood. |

Project Aether was developed to compete in the 30,000 ft Commercial-Off-The-Shelf (COTS) solid propulsion category of the 2022 Spaceport America Cup and the 2020 Virtual Australian Universities Rocket Competition. This visually distinctive launch vehicle features a transition section that tapers from a 6" diameter forward tube down to a 3.89" minimum diameter, non-uniform thickness rear tube, onto which four fins are surface mounted. Integrated within the forward body tube is a 4 kg, 3U CubeSat experimental payload, designed to investigate aerodynamic heating throughout flight with the use of a thermochromic paint. Aether utilised a single-bay, dual event recovery system that consisted of separation event at apogee, and a main parachute release with Tender Descenders at 1,000 ft upon descent. The team extensively used its in-house developed 6 degree of freedom trajectory simulator, SATURN, to influence design choices and promote a high level of competitiveness in the 30,000 ft category.

| Airframe Information | 3774 mm |

| Airframe Diameter | 156 mm to 104 mm transition |

| Motor | O3400 |

| Peak Thrust | 4699 N |

| Total Impulse | 21041 Ns |

| Burn Time | 6.14 s |

| Mass with no motor | 16.4 kg |

| Mass with motor | 33.2 kg |

| Project Leads | 2022: Isaac Alderton & Yog Shah 2021: George Coe & Thomas Whitehead 2020: Nathan Bui & Tom Mackellar |

| Competitions | 3rd - 2020 Virtual Australian Universities Rocket Competition - 30K COTS Category 6th - 2022 Spaceport America Cup - 30K COTS Category |

| Payload | Skin Friction Determination - Study thermochromic pigments that change colour in response to an increase in temperature to determine skin friction on the body of the rocket |

Project Icarus is the team's first sounding rocket developed to compete in the Intercollegiate Rocket Engineering Competition (IREC) known as Spaceport America Cup. Competing in the 10,000 ft Commercial-Off-The-Shelf (COTS) solid propulsion category the project represented major growth for the then 66-member team featuring an airbrake control system alongside a mechanically released 3U CubeSat payload. Integrated into the 3-U payload was the second iteration of a student-developed Artificial Neurovestibular System unit, used to investigate the effects of parabolic flight on human perceptions of acceleration. The scientific payload was designed to be released from the rocket at 3,000 ft to demonstrate the mechanical release system before deploying independent recovery systems. Further, a single degree of control authority was implemented into the launch vehicle through an air-brake control system, used to maintain a close-to-nominal trajectory throughout flight and precisely achieve the 10,000 ft altitude target. Atop the system itself, Project Icarus represents an improvement in all aspects of rocket development, ranging from aerostructures manufacturing and dynamics simulations to deployment systems and team logistics.

| Airframe Length | 3335 mm |

| Airframe Diameter | 156 mm |

| Motor | M3400 |

| Peak Thrust | 3898 N |

| Total Impulse | 9990 Ns |

| Burn Time | 2.92 s |

| Mass with no motor | 15.1 kg |

| Mass with motor | 23.2 kg |

| Project Leads | 2021: James MacKinnon & Matthew Sharkey 2020: Ben McAnulty & Emma Chapman |

| Competitions | 3rd - 2020 Virtual Australian Universities Rocket Competition - 10K COTS Category 2nd - 2021 Virtual Spaceport America Cup - 10K COTS Category |

| Payload | Artificial Neuro-vestibular System - Iteration 2 - Study the effect of spaceflight on the human neuro vestibular apparatus |

Hyperion was Monash High Powered Rocketry's first rocket developed to compete in the 30,000 ft Commercial-Off-The-Shelf (COTS) solid propulsion category, of which it did so in the 2019 Australian Universities Rocket Competition. Flying on a Cesaroni Technologies N5800 with a thrust to weight ratio of 19.7, Hyperion carried a 4kg scientific payload, equipped with telemetry sensors and a scientific experiment investigating the coagulation of particles in a weightless, vacuum environment; conditions akin to those found during the formation of celestial bodies. To ensure safe recovery, Hyperion utilised a dual deployment system with a custom designed Gas Operated Deployment System (GODS) for its primary deployment and an independent redundancy deployment system operated by black powder in the case of main system failure. Further, Hyperion’s flight stability was verified through trajectory simulation using both OpenRocket and the teams in-house developed 6 degree of freedom trajectory simulator, SATURN. Afterwhich, flight data also offered the team invaluable data to fine tune SATURN for more accurate future trajectory analysis of Monash HPR rockets.

| Airframe Length | 3551 mm |

| Airframe Diameter | 133 mm |

| Motor | N5800 |

| Peak Thrust | 6957 N |

| Total Impulse | 20368 Ns |

| Burn Time | 3.53 s |

| Mass with no motor | 20.5 kg |

| Mass with motor | 35.4 kg |

| Project Leads | Team Endeavour |

| Competitions | 2nd - 2019 Australian Universities Rocket Competition 30K COTS Category |

| Payload | Formation of dust aggregates - Study colliding dust particles in a vacuum chamber in microgravity conditions |

Athena was the beginning for Monash High Powered Rocketry and the first ever team rocket developed. It was designed to compete in the 10,000 ft Commercial-Off-The-Shelf (COTS) solid propulsion category, of which it did so in the 2019 Australian Universities Rocket Competition in Queensland. Athena flew on a Cesaroni Technologies M840 and was chosen due to the low maximum thrust and long burn time that prevented Athena from reaching transonic speed. This is further reflected in a thrust-to-weight ratio of 3.7 and was critical in developing the teams capacity as for the first team rocket of its class it reduced the structural loading and simplified the analysis process. Athena carried a four-kilogram scientific payload equipped with inertial and atmospheric sensors, and a scientific apparatus to simulate the inner structures of the ear and to model their behaviour during parabolic flight, investigating the effects on the perceived human disorientation. Additionally, recovery of Athena consisted of a custom designed Gas Operated Deployment System (GODS) and an independent black powder redundant deployment system. The development of Athena also allowed the team to reflect on its processes and identify that in future endeavours that better management of the internal and external influences on the project would produce a smoother development process.

| Airframe Length | 3020 mm |

| Airframe Diameter | 131 mm |

| Motor | M840 |

| Peak Thrust | 1980 N |

| Total Impulse | 7520 Ns |

| Burn Time | 8.96 s |

| Mass with no motor | 17.7 kg |

| Mass with motor | 24.7 kg |

| Project Leads | Team Endeavour |

| Competitions | 4th - 2019 Australian Universities Rocket Competition |

| Payload | Artificial Neuro-vestibular System - Iteration 1 - Study the effect of spaceflight on the human neuro vestibular apparatus |